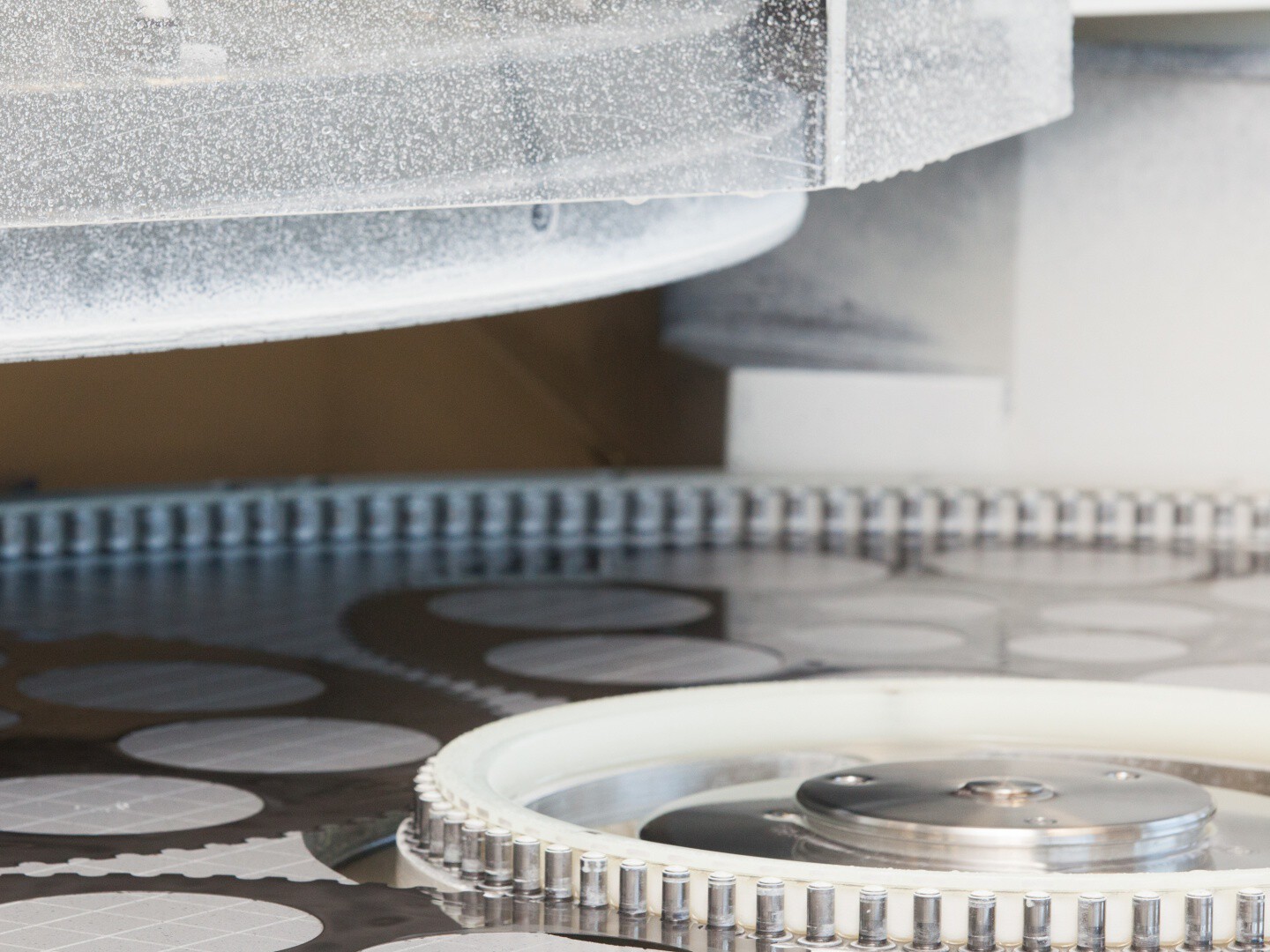

Surface finishing to perfection

Aachener Quarzglas offers its customers a manufacturing depth that covers all processing steps along the production process of complex components made from quartz glass, technical glass, and glass ceramics. The polishing of glass and glass ceramic components completes the manufacturing portfolio at the Aachen production site.

Quartz glass and technical glass ceramics are high-tech materials whose further processing requires years of experience and mastery of various key technologies. For the production of optical glasses, we use modern single- and double-sided polishing machines. Additionally, high precision is also achievable through hand polishing, laser polishing, and flame polishing.

The polishing techniques available are optimally tailored to the individual quartz glass and glass ceramic components, allowing almost all desired contours and contour combinations to be polished. This ensures that Aachener Quarzglas provides you with precise and process-optimized surface finishing for one-off and series products made from optical quartz glass, borosilicate glass, float glass, ceramics, and other optical materials.

Our processing capabilities

Our versatile processing methods ensure the highest precision and perfect surface quality for glass and glass ceramic components:

- Lapping – High-precision planar processing for extremely smooth and dimensionally accurate surfaces.

- Polishing – Refining the surface structure for maximum optical clarity and quality.

- Edge processing – Precise edge finishing for the highest dimensional accuracy and breakage resistance.

- Cleaning – Careful final cleaning for particle-free and residue-free glass surfaces.

- Laser polishing – Non-contact high-precision polishing for mirror-smooth surfaces and minimal roughness.

Custom solutions

We offer custom solutions for optical applications that require the highest precision and quality:

- Plano optics – High-precision optical components with excellent flatness for scientific and industrial applications.

- Optical access – Custom-designed glass solutions for clear, durable viewports in demanding environments.

- Prisms – Precision-crafted glass prisms for light direction, metrology, and optical systems.

- Custom solutions – Tailored glass processing for unique requirements and specialized applications.

Materials used

We process high-quality materials that are distinguished by their unique properties, making them suitable for demanding applications:

- Quartz glass – High-purity material with excellent temperature resistance, chemical resistance, and optical clarity.

- Borosilicate glass – Robust specialty glass with high thermal shock resistance and excellent chemical stability.

- Float glass – Versatile flat glass with a uniform surface and high transparency for a wide range of applications.