High-tech machine park and quartz glass expertise

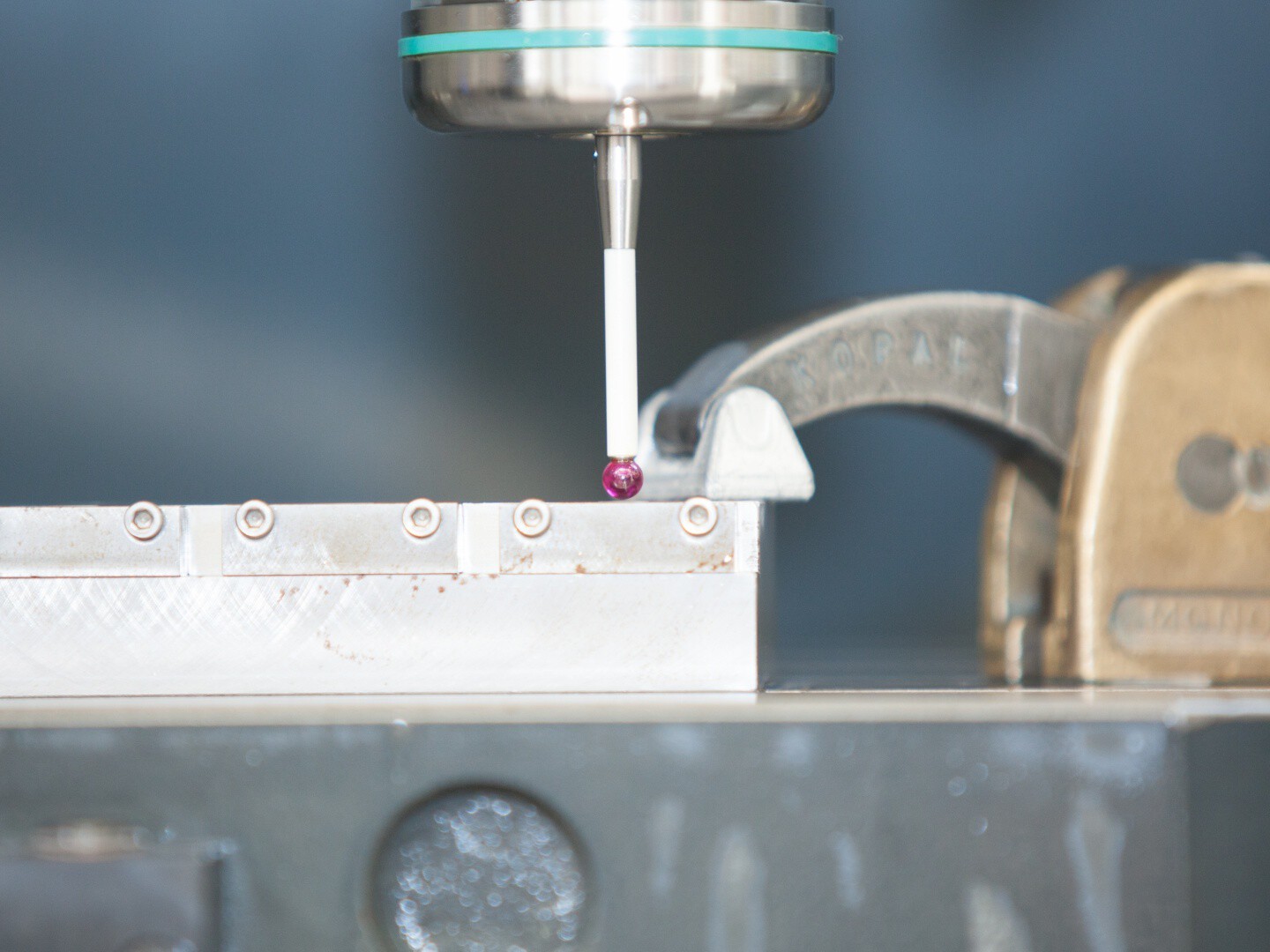

On a production area of 2,500 square meters, more than 100 specialized machines are available for the grinding of quartz glass, borosilicate glass, and technical ceramics. Modern technologies such as CNC 5-axis milling and ultrasonic processing are used here, ensuring precise processing of the valuable workpieces.

Aachener Quarzglas has more than 40 years of experience in glass and ceramic processing. Thanks to this expertise, we master all techniques used in the mechanical processing of quartz glass, technical glass, and technical ceramics. At the request of our customers, we manufacture glass and ceramic components in almost any shape while adhering to highly precise manufacturing tolerances.

Our processing capabilities

Aachener Quarzglas stands for the highest precision and years of experience in processing quartz glass, borosilicate glass, and technical ceramics. With state-of-the-art manufacturing technologies and over 100 specialized machines, we ensure the exact implementation of even the most demanding customer requirements.

- Turning – High-precision turning for complex geometries and tight manufacturing tolerances.

- Milling – CNC-controlled milling techniques for precise contours and detailed machining.

- Blasting – Surface treatment through precise blasting methods for refinement and cleaning.

- Surface Grinding – Perfect flatness and highest surface quality through modern grinding technologies.

- Water Jet Cutting – Material-friendly cutting with the highest precision for delicate components.

- Honing – Fine machining for the highest dimensional accuracy and perfect surface quality.

Custom solutions

In addition to various processing options, we offer custom solutions for a wide range of applications:

Materials used

We process a variety of high-quality materials for a wide range of technical and optical applications:

- Fused Silica – Especially pure and temperature-resistant material for high-tech applications.

- Borosilicate glass – Durable glass with high chemical resistance.

- Float glass – High-quality glass for optical and industrial uses.

- Ceramics – Technical high-performance ceramics for demanding applications.